Polymer fractionation

CSF

Continuous Spin Fractionation

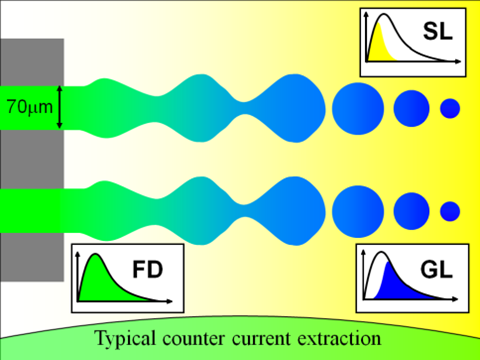

The patented "Continuous Spin Fractionation" (CSF) is a large scale fractionation technique that is based on liquid-liquid phase separation. As core item it uses spinning nozzles, like they are applied in the fibre industry. The feed is pressed through these nozzle in order to produce a large number (one spinning nozzle has about 1000 holes) of very thin threads with diameters in the range of 60-100 mm. Because of the Rayleigh instability these threads break immediately up into tinny droplets of typically 50 mm in diameter with a high surface to volume ratio (schematically depicted in the following figure). Due to the short distances of transportation the easier soluble component can leave the droplets much faster and equilibrium conditions are reached immediately enabling the realisation of high throughputs.

Functional principle of CSF. The feed (FD) is pressed through a spinning nozzle into the extracting agent. The threads of the viscous polymer solution break up into tiny droplets. The better soluble macromolecule can be easily extracted because of the short distance of transport. The droplets, freed from the low molecular weight material, contain the gel fraction (GL) whereas the continuos phase comprises the sol fraction (SL). The insets show the respective differential molecular weight distriubtions. Also indicated (identical scale) is the dimension of a typical droplet in a conventional extraction experiments.

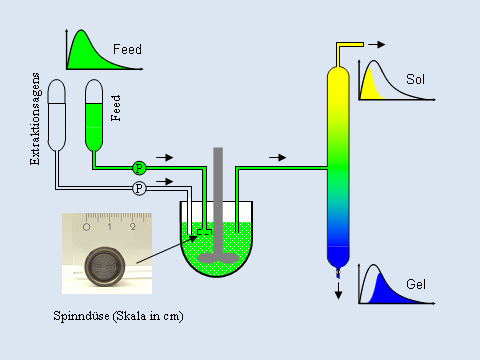

A schema of a typical CSF setup is shown in the next figure.

It mainly consists of a mixing vessel into which the extracting agent is pumped freely and the feed through a spinning nozzle. From this container the mixture is continuously transported into a device that allows macroscopic phase separation. In the simplest case this is a column in which the phases separate due to their difference in density. In case of too similar densities of the coexisting phases or if high throughputs are desired continuously working centrifuges can be used.

Even with a laboratory scale device of rather low capacity it is possible to reach polymer throughputs in the order of 10-100g/hour. It is obvious that modifications, like the use of more spinning nozzles, a suitable mixing vessel, and a centrifugal separator to detach sol and gel, make virtually any size of fractions accessible.

Scheme of the CSF: Feed (FD) an extracting agent (EA) are transported by mean of pumps into the mixing vessel, whereas the feed is spun through a spinning nozzle into a vigorously stirred vessel. The two phase mixture produced in this manner are transferred into a seperation column where one phase sediments and leaves at the lower end, whereas the other phase exits at the upper end. The differential molecular weight distributions of the initial polymer and the two obtained fractions are depicted in the inserts.