Glossary

A

Amplitude

The amplitude is the maximum value of an oscillatory movement.

Amplitude sweep

In the amplitude sweep, the amplitude of the deformation - or alternatively the amplitude of the shear stress - is varied and the frequency is kept constant. The storage modulus G' and the loss modulus G'' are obtained as measured variables against the deformation and the shear stress, respectively.

Angular frequency w

The angular frequency w (also circular frequency) indicates how quickly an oscillation occurs, i.e. it indicates the swept phase angle of the oscillation per period of time. It is calculated from the frequency f:

Unit: [1/s]

The angular frequency is a possible measurement specification at oscillatory tests.

C

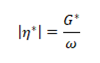

Complex viscosity |h*|

Oscillatory tests deliver beside storage modulus G' and loss modulus G'' also the so-called complex viscosity |h*|. It is calculated from the complex shear modulus G* and the angular frequency w:

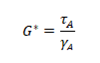

The complex shear modulug G* ist calculated from the amplitude of the shear stress tA and the amplitude of the deformation gA:

Unit: [Pa s]

Creep behaviour

If a defined force affect on a (solid) sample, the deformation of the sample due to the force effect is descriped by the creep behavioiur.

D

Deformation

The term deformation is understood in the broadest sense to mean the deformation of a body.

In rheology, deformation is also referred to as shear deformation g. This refers to the quotation of the deflection s of the measurement geometry to the shear gap h.

The measurement value does not have a unit, but is usually given as a percentage.

Dynamic viscosity h

The dynamic viscosity h (also known as shear viscosity) is the return value of the fluidity f of a sample. This in turn is a measure of the flowability of the sample.

Unit: [1 Pa s] = [1.000 cP]

E

Extensional viscosity

The velocity gradients are or point in the same direction.

The extensional viscosity of Newtonian fluids can usually be calculated using a constant ratio from the shear viscosity. For non-Newtonian liquids this ratio is no longer constant, i.e. for these liquids the extensional viscosity must be determined experimentally using an extensional viscometer (see extensional rheology).

Unit: [Pa s]

F

Frequency

The frequency is the repetitions of a periodic process (e.g. vibration).

Unit: [1 Hz] = [1 1/s]

Frequency sweep

During the frequency sweep, the frequency of the oscillation is varied and the amplitude of the deformation - or alternatively the amplitude of the shear stress - is kept constant. For evaluation, the measured variables storage modulus G' and loss modulus G'' are plotted against the frequency.

I

Ideal viscosity

Ideal viscous flow behavior (also: Newtonian flow behavior) means that the viscosity is independent of the shear rate. This behavior is found in homogeneous low-molecular fluids, e.g. in lubricating oils.

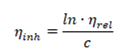

Inherent viscosity hinh

The inherent viscosity is calculated from the relative viscosity hrel and the polymer concentration c.

Unit: [1 dL/g]

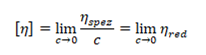

Intrinsic viscosity [h]

The intrinsic viscosity [h] is a hypothetic viscosity of a hypothetic concentration 0. It is a characteristic value for a polymer solution and depends on the polymer and its characteristics (chemistry, molecular weight, topology, branching, etc.) as well as on solvent and temperature.

The determination of the intrinsic viscosity is done by capillary viscometry with the specific viscosity hspec or the reduced viscosity hred.

Unit: [mL/g]

K

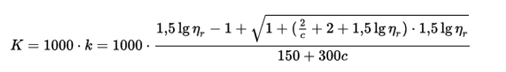

K-value

The K-value is calculated with this formula:

Kinematic viscosity n

By means of capillary viscometry the kinematic viscosity can be calculated with the viscometer constant K and the flow time of the solution t:

Unit: [m^2/s] (outdated: 1 St (Stokes) = 10^-4 m^2/s)

Kuhn-Mark-Houwink relation

The Kuhn-Mark-Houwink relation is an empiric found correlation between the molar mass of a polymer (more exact: viscosity average molar mass) M and the intrinsic viscosity [h] for this polymer in a certain solvent and at a certain temperature. The parameters K and a are constants, which have to be determined experimentally for every polymer/solvent pair at a certain temperature (e.g. by means of capillary viscometry).

The Kuhn-Mark-Houwink relation makes it possible to correlate the determined intrinsic viscosity with the molar mass of the polymer, if the constants K and a are known. Additionally the relation is used to determine the size exclusion chromatography to polymers, which are not available as standards and expands the application of this testing method considerably.

L

Linear-viscoelastic region

The linear-viscoelastic LVE region is determined by amplitude sweeps. It is the region, in which the determined storage modulus G' and loss modulus G'' show constant values (plateau value).

Loss modulus G''

The so-called loss modulus G'' is a measure at oscillatory measurements. It represents the viscous portion of the visco-elastic behaviour / fluid behaviour of the sample.

M

Molar mass

The molar mass (also molecular weight) is the mass m per amount of substance n:

Due to a different distribution of chain lenghts, the molar mass of polymers is differentiated between number average molar mass Mn, weight average molar mass Mw, viscosity average molar mass Mh, and centrifuge average molar mass Mz (see also polymer).

Unit: [kg/mol]

N

R

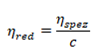

Reduced viscosity hred

The reduced viscosity hred is the quotient of the specific viscosity hspec and the concentration c:

The reduced viscosity is a typical measure at capillary viscometry.

Unit: [mL/g]

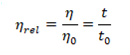

Relative viscosity hrel

The relative viscosity is calculated from the viscosity of a polymer solution h and the viscosity of the used solvent h0 resp. from the flow time of the polymer solution t and the flow time of the used solvent t0 determined by means of capillary viscometry.

Unit: [1]

S

Shear rate

At the 2-Plate-Model the shear rate is the quotient of the velocity v and the gap of the plates h:

Unit: [1/s]

Shear-thickening

The viscosity of shear-thickening fluids increases with increasing shear rate.

Shear-thinning

The viscosity of shear-thinning fluids decreases with increasing shear rate.

Shear stress t

Shear stress is the quotient of shear force F and shear area A:

Unit: [Pa]

Shear viscosity

Shear viscosity is defined as viscosity of a sample under shear stress. At shear the motion vector perpendicular to the velocity gradient.

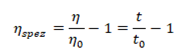

Specific viscosity hspec

The specific viscosity hspec is calculated from the viscosity of the polymer solution h and the viscosity of the used solvent h0. At capillary viscometry the specific viscosity can be determined from the flow time of the polymer solution t and the flow time of the used solvent t0.

Unit: [1]

Storage modulus G'

The storage modulus G' can be received from oscillatory measurements. It represents the elastic portion of the visco-elastic behaviour / solid state behaviour of the sample.

Structure breakdown

The term structure breakdown stands for the decrease of the viscosity under shear as function of time.

See Thixotropy

Structure recovery

Structure recovery is the increase of the viscosity as function of time as soon as the sample is resting.

Unter Strukturaufbau (auch Strukturwiederaufbau) versteht man die Zunahme der Viskosität als Funktion der Zeit, wenn sich die Probe in Ruhe befindet. This is preceded by shearing, which leads to a structure breakdown.

See Thixotropy

T

Thixotropy

The term thixotropy stands for the decrease of viscosity under shear as function of time as well as for the increase of viscosity as function of time as soon as the sample is not or only a little is sheared. So thixotropy means the change of viscosity with time. Alternatively the terms structure breakdown (under shear) and structure recovery (under rest) is used.

The oppositive of thixotropic behaviour is a rheopex behaviour: Under shear the viscosity incrases and under rest the viscosity decreases.

V

Viscosity

Viscosity is understood as resistance to flow of liquids or gases. The viscosity is higher, the viscous a sample is. The viscosity is lower, the thin fluid a sample is.

Viscosity curve

The viscosity curve is the plot of dynamic viscosity versus shear rate. Often the viscosity curve is also called flow curve.

Viscosity index

The viscosity index of lubricants is the temperature dependence of its kinematic viscosity. A lubricant with low viscosity index shows a stronger temperature dependence of the change of viscosity as a lubricant with higher viscosity index.

Viscosity number

See Reduced viscosity

Viscosity ratio

Viscosity ratio is the quotient of the actual kinematic viscosity n of the lubricant to the kinematic viscosity required for adequate lubrication n1:

A fully developed lubricating film is only achieved at a viscosity ratio of 1.

Y

Yield point

The lowest needed shear stress, which is needed to let a sample flow, is called yield point. If a sample is exposed to shear stress higher than its yield point, the sample behaves like a liquid. If a sample is exposed to shear stress lower than its yield point, it behaves like a solid.